Connectivity - the basis for local and global data exchange - Part 1

Published:

WHY move the local machine world into the cloud at all? Is local connectivity on the machine side not sufficient? If I want to bring my local machine world into the cloud, which data integration strategy is the right one for me? These are precisely the questions I address within this blogpost and the underlying whitepaper.

Why move the local machine world into the cloud at all?

Manufacturer’s View

Why should a component, machinery, or plant manufacturer even attempt to get production data into the cloud? They could also deliver smart software that runs exclusively locally at the customer’s site. Such fundamental questions are entirely justified when it comes to connectivity, which is why this blogpost aims to answer these exact questions.

Suppose the manufacturer decides to deliver its physical product along with a well-defined data interface and local software that performs certain analyses for the customer. If both the data interface and the analytics software are of high quality, this can lead to a positive customer experience. However, with this approach, the manufacturer faces several disadvantages:

Limited Customer Insights: They have little to no information about how the customer uses the product itself and the associated software and can therefore hardly offer proactive support. Instead, they can only reactively respond to customer problems.

Static Knowledge Integration: They can only incorporate already known engineering knowledge into the analytics software. There can be no talk of data-driven approaches or even data-driven business models, as new features based on collected data cannot be rolled out. This is because the data generated in operation is only stored locally by each user.

Challenging Software Updates: An update of the analytics software is only possible to a limited extent. Updates can only be carried out if the software runs on computers with internet access and, in addition, the customer actively agrees to the software update. While these prerequisites are met for the classic app on the smartphone, they are anything but standard in a production hall. Over time, this often leads to high maintenance efforts for different versions of the software. Even the quick end of support for older software versions, long accepted in the smartphone sector, is anything but usual or accepted in the industrial environment.

OS Compatibility Issues: The manufacturer faces a tough choice: Either they develop their software for just one operating system, thereby reducing their overall potential customer base, or they must develop and maintain their software for multiple operating systems.

When the data - and at this point, we are not talking about sensitive personal data - lands in the cloud, the following advantages arise:

Enhanced Data Insight: The manufacturer gains information about how its product is being used by customers. In cases of misuse, the manufacturer can offer assistance, which increases customer loyalty and leads to numerous touchpoints with the customer. Moreover, the manufacturer can use the application knowledge for the further development of its product.

Ability to enter new Business models: Based on real data from its customers, the manufacturer can develop intelligent services such as anomaly detection, predictive maintenance, visual inspection, etc.. This opens up entirely new business models for the manufacturer. The user also benefits, as the product continuously improves and lessons can be learned from failures at other customers, which in turn improves the service for each individual user.

Simplicity and control over software updates: Since the manufacturer itself operates the software in the cloud, providing the end customer with “just” a frontend or even additional data interfaces, it retains full control over software updates, is independent of its customers’ preferred operating systems, and can even change fundamental data structures retroactively. The only thing it needs to ensure is that there are no logical inconsistencies compared to the already known frontend for the customer and should version the data interfaces if they exist.

Advanced Computing Resources: More powerful computing resources are available in the cloud than locally at the customer’s site. For example, streaming services can be built on a large scale that would not be economically feasible for an individual customer or could not be executed with limited computing resources, but make sense for the totality of the data.

As the previous text shows, there are numerous arguments from the perspective of component, machinery, or plant manufacturers for moving their customers’ local machine environments into the cloud. But what about the arguments from the customer’s perspective, that is, the machine operator?

Machine Operator’s View

For Machine Operators, there is a trade-off between data sovereignty/security and service orientation. If the service concept is a priority, meaning the customer places high value on proactive support and reliable services like anomaly detection or predictive maintenance, then they are likely supporters of transferring local machine data to the cloud.

However, if data sovereignty is their main concern, they might categorically reject the transfer of data to the cloud. According to my experience, a shift in thinking is currently occurring: While cloud connections in the industrial environment were categorically rejected a few years ago, such connections are now continuously increasing in the industrial sector. The reasons for this are multifaceted, and only the two most significant ones will be mentioned here:

- The increasing “contact” with the cloud through other IT systems such as CRM systems or ERP systems being moved to the cloud reduces the initial fears and barriers.

- Concerns regarding data security have been addressed with numerous solutions in the form of anonymization, encryption, etc.

Nevertheless, every component, machinery, or plant manufacturer facing the “cloud decision” described in this chapter should thoroughly engage with their customers’ needs and determine how their customers handle the aforementioned trade-off.

In the further course of this blogpost, it is assumed that the decision has been made to transfer local machine data to the cloud.

Strategic aspects of connectivity: Which type of data integration is the ‘right’ one?

Once the decision has been made to move local machine data to the cloud, the question of the right integration strategy arises. A fundamental distinction must be made between horizontal and vertical data integration. Vertical data integration means that the component, machine or system manufacturer, as the future provider of a digital product, supplies all the hardware required to transfer the data from the sensor to the cloud. In addition to the sensor technology and a control unit (PLC/PLC), this also includes a gateway that has an internet connection and can therefore send the resulting data to the cloud. Horizontal data integration, on the other hand, assumes that the customer of the component, machine or system manufacturer provides the gateway himself (often in the form of an industrial PC) and that the hardware performance of the component, machine or system manufacturer is limited to the sensors and control unit (PLC/PLC). With this data integration strategy, it is important that the control unit publishes the resulting data in a standard format so that it is relatively easy for the end customer to receive this data on the industrial PC and send it to the cloud.

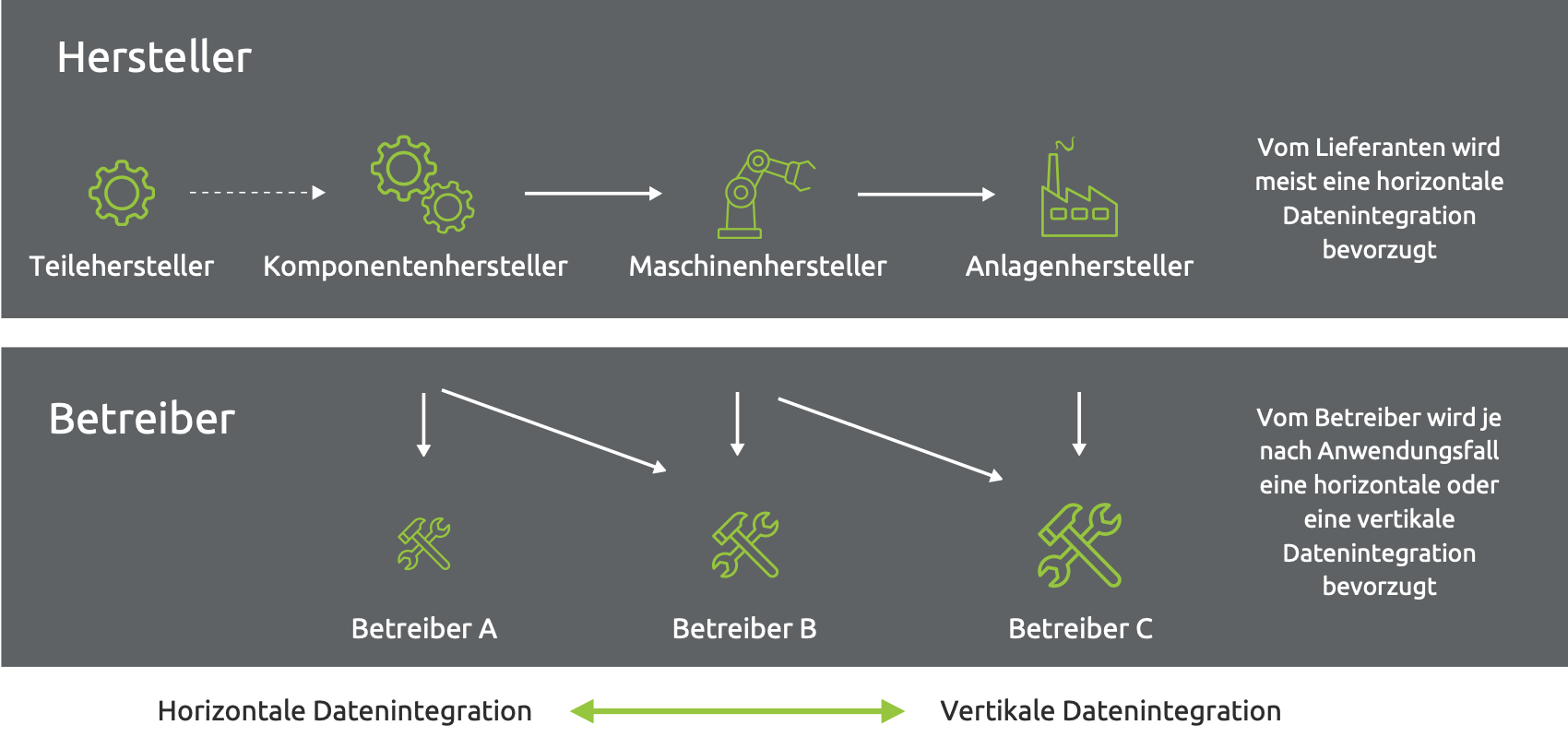

The question now arises as to which type of data integration is the right one and what advantages and disadvantages the two strategies entail. To answer this question, the component, machine or plant manufacturer should first categorise their company on the manufacturer side. As Figure 1 illustrates, it is helpful for a company to be clear about whether it is more of a parts, component, machine or system manufacturer.

In the illustration, this means deciding in favour of one of the green symbols in the manufacturer area. Depending on the manufacturer and product portfolio, this categorisation may be very easy or quite difficult.

The next step is to analyse to which type of customer the component, machine or system manufacturer mainly sells its physical product. In Figure 2, this means following the arrows pointing away from the previously selected manufacturer symbol.

As a general rule, if you are more likely to sell your physical product to another manufacturer, you should opt for horizontal data integration. This is because a system manufacturer that integrates ten different machines into its system does not want to manage ten gateways that independently send data to the cloud. Instead, the plant manufacturer wants to send the data from the different machines to the cloud via a single industrial PC in a simple and standardised way.

Let’s take the machine manufacturer as an example: does he sell more to an operator who uses his machine to produce a product in large quantities and then sells it to his customers? Or is the direct customer more likely to be a plant manufacturer who integrates the machine manufacturer’s machine - along with many other machines - into his plant? machines - into his plant? Does the component, machine or system manufacturer or system manufacturer sells its physical product to an operator, it depends the importance of the product in the customer’s overall production. If the product is the core of the customer’s value creation and therefore accounts for a high proportion of the customer’s overall production, the customer will tend to favour the vertical integration approach, as it does not use its own industrial PC at all. However, if the product only covers a small part of the customer’s value creation, the same argument applies as for the plant manufacturer: the customer does not want to manage ten gateways that independently send data to the cloud.

The appropriate type of data integration is therefore strongly dependent on the type of customer of the component, machine or system manufacturer. It is also important to consider the following advantages of both types of integration. The advantages of vertical integration are also to be understood as disadvantages of horizontal integration and vice versa.

Advantages of vertical integration:

- Complete control over the data flow from the sensor to the cloud. For example, if the component, machine or system manufacturer wants to increase the sampling rate of their vibration sensor from two kilohertz to ten kilohertz (of course, the sensor must be able to do this), they can do so via a software update.

- This ensures that the digital product does not fail at the specific customer due to the gateway’s Internet access, as everything is provided from a single source. from a single source. No compatibility problems with different industrial PCs.

Advantages of horizontal integration:

- No costs for a gateway, which may significantly increase the price of a digital product.

- As the customer is responsible for routing the data to the cloud (it is certainly possible to incentivise the customer to do this), the manufacturer is not made responsible in the event of connection problems.

Leave a Comment