How to get from Sensor Data to a digital product

Published:

“We should digitalise our product! Digital twin, predictive maintenance, intelligent quality control: can’t we offer that too?” Service managers from the mechanical engineering sector are increasingly confronted with questions like these. Do such questions sound familiar to you? This blogpost together with follow up blogposts as well as the underlying whitepaper provides the technical and strategic answers as well as a fact-based introduction to the world of product digitalisation.

This includes:

- The WHY: The upper management level, which highlights the arguments for or against product digitalisation in general.

- The HOW: The strategic level, which highlights which building blocks are required on the path from sensor to digital product and what purpose they fulfil.

- The WHAT: The technical-operational level, in which the details and difficulties of the individual building blocks are illuminated.

Let’s start with the WHY

Why develop digital products at all?

Without digital products, an ‘as a service’ model is not possible. How can you let your customer pay for just what he uses if you dont have a digital product that collects data and gives you the information about what the customer acutally used? And without an ‘as a service’ model, there is a risk of losing market share in the long term. Subscription models and ‘pay-as-you-use’ approaches have long been ubiquitous. For products that are digitally accessible, such as music and video services or cloud infrastructures, these approaches are already the clear winners. Former leaders who continued to rely on the ‘invest once and own forever’ model have largely been forced out of the market.

Furthermore, there are advantages regarding Research & Development: Product digitalisation enables data access to the product in its actual application. This in turn enables data-driven further development of the product that goes far beyond the possibilities of the company’s own test benches.

Last but not least, Product digitalisation leads to a significant increase in proximity to the customer. This is because the digital product creates numerous new points of contact, such as warnings from applications, direct contact from support due to unusual sensor values, etc.

But what does this have to do with the manufacturing industry?

Digital services in the manufacturing industry can generate additional business. Some companies have started to equip their products with sensor technology and build up data pipelines with the aim of selling digital services such as predictive maintenance, automated quality control, etc. in the long term. But even companies that have not yet opened up new business areas through digital services are feeling the pressure from customers who are demanding data interfaces to systems, machines and components.

What comes after the digital product?

Visionaries and some pioneers are already moving to the next stage of development: those who are able to offer reliable predictive maintenance services for their machines are also in a position to market the product in a subscription model or even in the form of a ‘pay-as-you-go’ approach. This results in lower barriers to entry, especially for capital-intensive machines, continuous income, additional service business and significantly stronger customer loyalty.

Let’s have a look HOW we can get to a digital product

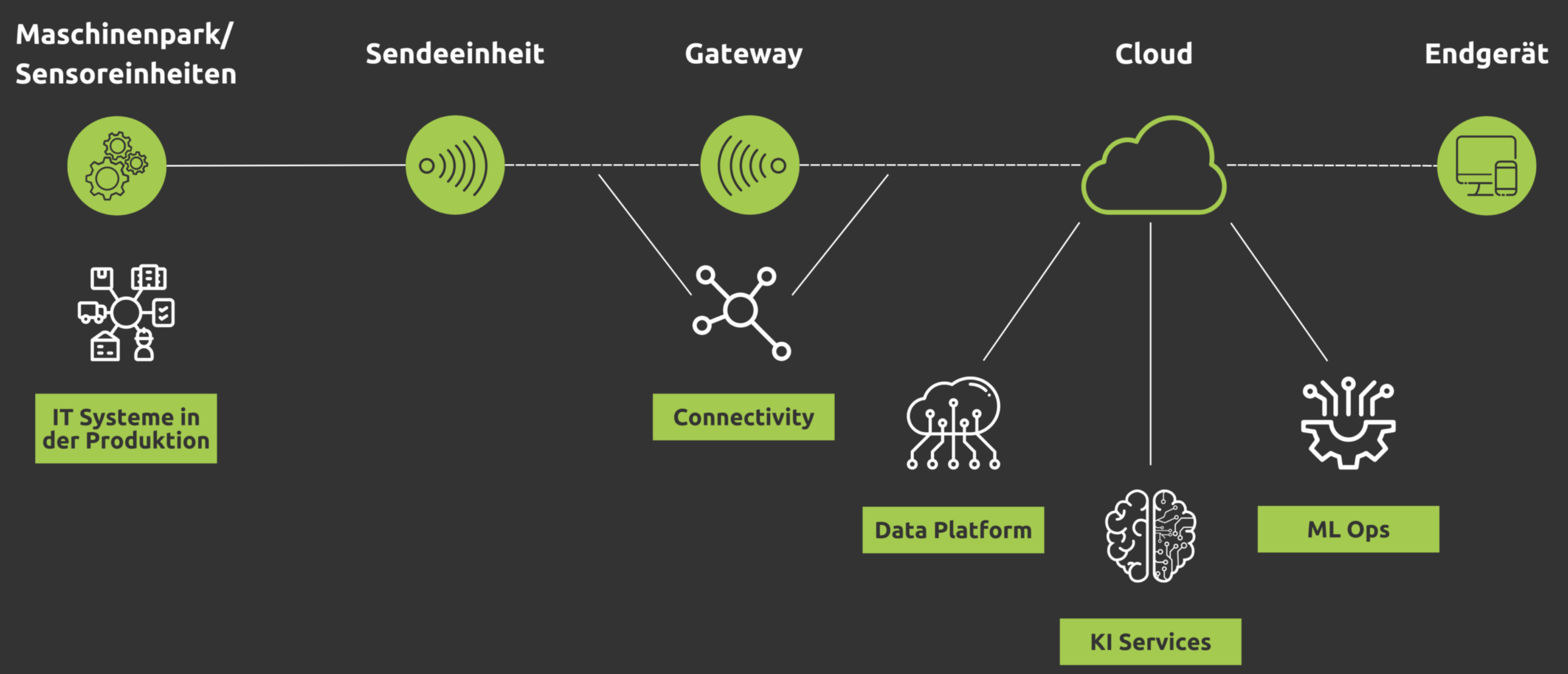

There are several skills needed along the road from some sensors to a digital product. Those skills can be clustered into 4 categories: Connectivity, Data Platfrom, AI Services and MLOps following the data flow as illustrated in the figure below.

Connectivity

The digital transformation has ensured that increasing amounts of digital data are available along the industrial value chain: from simulation data in development and sensor data in production to digital maintenance reports and localisation data of moving machines. Connectivity - the ability of individual devices to connect to a network and exchange information - is a basic prerequisite for utilising the enormous amounts of digital data.

Data Platform

A data platform is the ‘link’ between IoT connectivity and AI services. It enables the seamless integration and consolidation of data from different sources and also acts as a robust basis for AI services. In addition, a data platform can offer data reliability, scalability and robustness while also taking into account the framework conditions for security, governance and costs.

AI Services

Gaining insights and knowledge from data along the production process can be a strategic success factor that, in addition to providing new products and services, can also help manufacturers to optimise processes, thereby increasing their efficiency and reducing costs at the same time. This makes them more competitive in a global, rapidly changing market.

MLOps

It is one thing to learn from your data and bring a machine learning model into production. But it a very different thing to develop your models in a way that ensures maintainability, extensibility & security of AI-based applications. This capability is summarised under the term MLOps, which means Machine Learning Operations.

The WHAT - the technical-operational level

But how is all of this done in technical detail? I will answer this question within my follow up posts. If you want to read through it all at onces, have a look at my Whitepaper So gelingt der Weg zum Digitalen Produkt

Leave a Comment